Here is how I made my own custom soap stamp.

What You Need:

molding clay (the kind you bake in the oven to harden, most craft stores have it)

detail tools

small box of resin or epoxy (you won't need more than a few ounces depending on the size of your stamp)

disposable cup

plastic spoon

duct tape

container to hold the epoxy and mold

toothpicks

printer & clear stickers (if copying an image)

1. First you'll need your molding clay and detail tools. I wanted my stamp to say the name of my company in a certain font, so I printed out what I wanted ahead of time on a clear stamp. If you're drawing freehand you can skip that. But make sure the surface of the clay is nice and flat so the entire image will show up in the imprint. You can use a rolling pin if you need a bigger surface to carve your image into the clay. Mine was the perfect size already, so I just cut the block of clay in half to get a rectangular stamp.

2. Using the detailing tool (I used the kind with the little ball on the ends to make smooth lines) draw or trace your image/text lightly into the molding clay. Note: Make sure to draw your image exactly how you want it to come out in the molding clay, NOT a mirror image, or you will get a backwards image/text. I made this mistake thinking I needed a mirror image carved to get the letters to imprint correctly and had to make another stamp.

3. Go over your lines to make deeper grooves into the clay. You'll want it deep enough so the resin will fill the grooves and make your stamp press in enough to leave a nice imprint in your soap. If you go too deep and the stamp cuts too far into your soap, you can always file down the stamp, but if you don't make it deep enough you'll have to start completely over and make a new one. I made my grooves about 1.5 millimeters deep. You won't need to bake the clay, it will be stiff enough to hold the shape and carving as is.

4. Once you are satisfied with your carving, place it inside of a box (I used a pudding box), or something that can hold the molding clay tightly against the edges and won't leak out the resin, and duct tape the edges to ensure there will be no leaks. You could even just use duct tape around the molding clay if you'd like, but it's pretty easy for the resin to leak out (I tried doing this with the first stamp I made), if you do use duct tape just make sure to use plenty of tape so you don't end up will all of your resin leaked out like I did. If using a cardboard box, you can duct tape the inside if you want a clean unmolding without any cardboard stuck the side. If you only care about the performance of the stamp and not the look, you can skip this. I did.

5. Mix the epoxy or resin in a disposable container, making sure to use equal parts (or even a bit more hardener) so the cast sets nice and hard. Mix well. The resin I used took over 48 hours to harden the first time and was still pretty bendable, so the second time I added just a bit more hardener to make the curing time quicker and the cast harder. Some resins only take a few hours to set. You can use any epoxy or resin, as long as it is a HARD finish.

6. Using a spoon, drizzle the epoxy onto the molding clay from a few inches high so it goes into the grooves. Notice the air bubbles, you may or may not end up with some in the epoxy, if so it's no big deal. Just take a toothpick and trace the grooves several times in good lighting and make sure you get any bubbles out of the grooves. You can even drag the bubbles up to the surface and pop them. The bubbles won't hurt your stamp as long as you don't have any in the grooves. This is probably the most important step of this tutorial. You want to make sure the entire image will imprint into the soap.

7. Read the directions included in the box the resin came in. You will need to wait the allotted time for your cast to harden before trying to unmold it. Mine was ready to go after a little less than 24 hours. Tap on the surface and squeeze the box to make sure it's fully set before trying to unmold. If it's ready, pull apart your mold and clean off the molding clay. You now have your stamp! The image will appear backwards but will turn out the correct way once stamped. You will probably need to trim the edges to get a flat surface and clean imprint. Lay it face down on a table and look to make sure the image is protruding evenly. At this stage your cast will still be soft enough to bend slightly if needed.

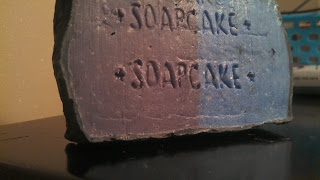

8. Test the stamp on a bar of soap, either new or maybe a week or two old if you have one, if not, it should work on a cured bar. I didn't need to make any adjustments to my stamp, but if yours cuts too deep just take some sandpaper and sand down the image a bit. And I mean just a bit! Don't sand too much off or you'll be left with a stamp that barely leaves an imprint.

And there you have it, your very own customized soap stamp, for a fraction of the cost of having one made! Mine cost me $12 as I already had everything but the epoxy. That's a heck of a lot better than 80 some dollars!

I hope you enjoyed this tutorial and enjoy your new soap stamp. The great part is you will probably will have only used a small portion of the epoxy, so you can make more stamps for no extra cost!

This is great! Thank you soooo much!

ReplyDeleteWonderful😘. Thank you so very much for that tutorial. I, too, am a soaper and was looking into the possibility of creating my very own soap stamp. Great post! Cheers!!

ReplyDeleteSincerely,

Michelle

Iam very happy to have such a blog here.I searched a lot and at last i find out the apt one..This blog is very informative for me and your knowledge about this topic is appreciable . Sohman Epoxy also contains a lot of information.This website also help me to deepen my knowledge..Just check this one also Jeffamine D230 surely you may get some more details about the topic.Thank you.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteSimply wish to say your article is as astonishing. The clarity in your post is simply great, and I could assume you are an expert on this subject. Same as your blog i found another one Sohman Epoxy .Actually I was looking for the same information on internet for LY 556 and came across your blog. I am impressed by the information that you have on this blog. Thanks a million and please keep up the gratifying work.

ReplyDelete