I just got my new order from LotionCrafter. I've been waiting forever to try some of these ingredients. I feel like a little kid at Christmas time when I'm digging through my package to see what's inside!

This week I'll be experimenting with new ingredients, and will be posting about each one. I've got Behenyl Alcohol which I'm probably the most excited for, Aluminum Oxide (microdermabrasion) Crystals, Cetyl Esters, Gingko Extract, Hibiscus Extract, Cyclomethicone, LipidThix, Olivem 300, Sodium Lactate Powder, and Lotionpro 165. I've got plans for each one of these. Sometimes I order things and when I get them, I forgot why I wanted them in the first place. I suggest writing down what it is you want to do with each ingredient when placing an order, so you don't get your lovely new ingredients and have no clue what to do with them!

Speaking of keeping notes, in my opinion that is probably the single most important thing for any homecrafter. You need to keep good notes on everything you make, every idea you have, thoughts about the products you make, and most importantly your recipes! I've heard people say they made something they loved and didn't take notes on it, and were never able to recreate it, even years later. So make sure you take good notes! You can also look back and see if something went wrong, why it happened. You can make any changes that need to be made, and recreate your product exactly each time.

Some things we'll be looking at this week are formulating with behenyl alcohol, cetyl esters, and lotionpro 165. I'll be writing about each ingredient. What they are used for, what they do, and what each brings to the table.

So tomorrow we'll begin with behenyl alcohol. We'll also be looking a little at adsorption and substantivity and how conditioner works, before getting into our first experiment: formulating a conditioner with behenyl alcohol. Tune in tomorrow for fun with formulating!

An adventure of cosmetics, science, and fresh ideas. Join me to learn about & make (and sometimes mistake) all things Bath & Body!

Monday, November 19, 2012

Thursday, November 8, 2012

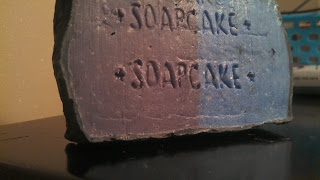

Soap stamp Tutorial

Custom soap stamps make soap unique and display your company name, logo or whatever you want right on your soap. So even without any packaging, customers can know who the soap is from. But they can be pretty costly. I've been wanting one, but the cheapest price I found on ordering a custom one was over $80 for a 1x1" stamp, so I looked into making my own. I found that using items I already had around my house, I could pretty easily make my very own stamp to say anything I want. The only thing I had to actually buy was epoxy resin. If you've been wanting to customize your soap and add a little extra something to it, this tutorial may be for you.

Here is how I made my own custom soap stamp.

What You Need:

molding clay (the kind you bake in the oven to harden, most craft stores have it)

detail tools

small box of resin or epoxy (you won't need more than a few ounces depending on the size of your stamp)

disposable cup

plastic spoon

duct tape

container to hold the epoxy and mold

toothpicks

printer & clear stickers (if copying an image)

1. First you'll need your molding clay and detail tools. I wanted my stamp to say the name of my company in a certain font, so I printed out what I wanted ahead of time on a clear stamp. If you're drawing freehand you can skip that. But make sure the surface of the clay is nice and flat so the entire image will show up in the imprint. You can use a rolling pin if you need a bigger surface to carve your image into the clay. Mine was the perfect size already, so I just cut the block of clay in half to get a rectangular stamp.

2. Using the detailing tool (I used the kind with the little ball on the ends to make smooth lines) draw or trace your image/text lightly into the molding clay. Note: Make sure to draw your image exactly how you want it to come out in the molding clay, NOT a mirror image, or you will get a backwards image/text. I made this mistake thinking I needed a mirror image carved to get the letters to imprint correctly and had to make another stamp.

3. Go over your lines to make deeper grooves into the clay. You'll want it deep enough so the resin will fill the grooves and make your stamp press in enough to leave a nice imprint in your soap. If you go too deep and the stamp cuts too far into your soap, you can always file down the stamp, but if you don't make it deep enough you'll have to start completely over and make a new one. I made my grooves about 1.5 millimeters deep. You won't need to bake the clay, it will be stiff enough to hold the shape and carving as is.

4. Once you are satisfied with your carving, place it inside of a box (I used a pudding box), or something that can hold the molding clay tightly against the edges and won't leak out the resin, and duct tape the edges to ensure there will be no leaks. You could even just use duct tape around the molding clay if you'd like, but it's pretty easy for the resin to leak out (I tried doing this with the first stamp I made), if you do use duct tape just make sure to use plenty of tape so you don't end up will all of your resin leaked out like I did. If using a cardboard box, you can duct tape the inside if you want a clean unmolding without any cardboard stuck the side. If you only care about the performance of the stamp and not the look, you can skip this. I did.

5. Mix the epoxy or resin in a disposable container, making sure to use equal parts (or even a bit more hardener) so the cast sets nice and hard. Mix well. The resin I used took over 48 hours to harden the first time and was still pretty bendable, so the second time I added just a bit more hardener to make the curing time quicker and the cast harder. Some resins only take a few hours to set. You can use any epoxy or resin, as long as it is a HARD finish.

6. Using a spoon, drizzle the epoxy onto the molding clay from a few inches high so it goes into the grooves. Notice the air bubbles, you may or may not end up with some in the epoxy, if so it's no big deal. Just take a toothpick and trace the grooves several times in good lighting and make sure you get any bubbles out of the grooves. You can even drag the bubbles up to the surface and pop them. The bubbles won't hurt your stamp as long as you don't have any in the grooves. This is probably the most important step of this tutorial. You want to make sure the entire image will imprint into the soap.

7. Read the directions included in the box the resin came in. You will need to wait the allotted time for your cast to harden before trying to unmold it. Mine was ready to go after a little less than 24 hours. Tap on the surface and squeeze the box to make sure it's fully set before trying to unmold. If it's ready, pull apart your mold and clean off the molding clay. You now have your stamp! The image will appear backwards but will turn out the correct way once stamped. You will probably need to trim the edges to get a flat surface and clean imprint. Lay it face down on a table and look to make sure the image is protruding evenly. At this stage your cast will still be soft enough to bend slightly if needed.

8. Test the stamp on a bar of soap, either new or maybe a week or two old if you have one, if not, it should work on a cured bar. I didn't need to make any adjustments to my stamp, but if yours cuts too deep just take some sandpaper and sand down the image a bit. And I mean just a bit! Don't sand too much off or you'll be left with a stamp that barely leaves an imprint.

And there you have it, your very own customized soap stamp, for a fraction of the cost of having one made! Mine cost me $12 as I already had everything but the epoxy. That's a heck of a lot better than 80 some dollars!

I hope you enjoyed this tutorial and enjoy your new soap stamp. The great part is you will probably will have only used a small portion of the epoxy, so you can make more stamps for no extra cost!

Here is how I made my own custom soap stamp.

What You Need:

molding clay (the kind you bake in the oven to harden, most craft stores have it)

detail tools

small box of resin or epoxy (you won't need more than a few ounces depending on the size of your stamp)

disposable cup

plastic spoon

duct tape

container to hold the epoxy and mold

toothpicks

printer & clear stickers (if copying an image)

1. First you'll need your molding clay and detail tools. I wanted my stamp to say the name of my company in a certain font, so I printed out what I wanted ahead of time on a clear stamp. If you're drawing freehand you can skip that. But make sure the surface of the clay is nice and flat so the entire image will show up in the imprint. You can use a rolling pin if you need a bigger surface to carve your image into the clay. Mine was the perfect size already, so I just cut the block of clay in half to get a rectangular stamp.

2. Using the detailing tool (I used the kind with the little ball on the ends to make smooth lines) draw or trace your image/text lightly into the molding clay. Note: Make sure to draw your image exactly how you want it to come out in the molding clay, NOT a mirror image, or you will get a backwards image/text. I made this mistake thinking I needed a mirror image carved to get the letters to imprint correctly and had to make another stamp.

3. Go over your lines to make deeper grooves into the clay. You'll want it deep enough so the resin will fill the grooves and make your stamp press in enough to leave a nice imprint in your soap. If you go too deep and the stamp cuts too far into your soap, you can always file down the stamp, but if you don't make it deep enough you'll have to start completely over and make a new one. I made my grooves about 1.5 millimeters deep. You won't need to bake the clay, it will be stiff enough to hold the shape and carving as is.

4. Once you are satisfied with your carving, place it inside of a box (I used a pudding box), or something that can hold the molding clay tightly against the edges and won't leak out the resin, and duct tape the edges to ensure there will be no leaks. You could even just use duct tape around the molding clay if you'd like, but it's pretty easy for the resin to leak out (I tried doing this with the first stamp I made), if you do use duct tape just make sure to use plenty of tape so you don't end up will all of your resin leaked out like I did. If using a cardboard box, you can duct tape the inside if you want a clean unmolding without any cardboard stuck the side. If you only care about the performance of the stamp and not the look, you can skip this. I did.

5. Mix the epoxy or resin in a disposable container, making sure to use equal parts (or even a bit more hardener) so the cast sets nice and hard. Mix well. The resin I used took over 48 hours to harden the first time and was still pretty bendable, so the second time I added just a bit more hardener to make the curing time quicker and the cast harder. Some resins only take a few hours to set. You can use any epoxy or resin, as long as it is a HARD finish.

6. Using a spoon, drizzle the epoxy onto the molding clay from a few inches high so it goes into the grooves. Notice the air bubbles, you may or may not end up with some in the epoxy, if so it's no big deal. Just take a toothpick and trace the grooves several times in good lighting and make sure you get any bubbles out of the grooves. You can even drag the bubbles up to the surface and pop them. The bubbles won't hurt your stamp as long as you don't have any in the grooves. This is probably the most important step of this tutorial. You want to make sure the entire image will imprint into the soap.

7. Read the directions included in the box the resin came in. You will need to wait the allotted time for your cast to harden before trying to unmold it. Mine was ready to go after a little less than 24 hours. Tap on the surface and squeeze the box to make sure it's fully set before trying to unmold. If it's ready, pull apart your mold and clean off the molding clay. You now have your stamp! The image will appear backwards but will turn out the correct way once stamped. You will probably need to trim the edges to get a flat surface and clean imprint. Lay it face down on a table and look to make sure the image is protruding evenly. At this stage your cast will still be soft enough to bend slightly if needed.

8. Test the stamp on a bar of soap, either new or maybe a week or two old if you have one, if not, it should work on a cured bar. I didn't need to make any adjustments to my stamp, but if yours cuts too deep just take some sandpaper and sand down the image a bit. And I mean just a bit! Don't sand too much off or you'll be left with a stamp that barely leaves an imprint.

And there you have it, your very own customized soap stamp, for a fraction of the cost of having one made! Mine cost me $12 as I already had everything but the epoxy. That's a heck of a lot better than 80 some dollars!

I hope you enjoyed this tutorial and enjoy your new soap stamp. The great part is you will probably will have only used a small portion of the epoxy, so you can make more stamps for no extra cost!

Sunday, November 4, 2012

Testing a new CP soap recipe

I've been making my own CP (cold process) soap recipes for a while now. I've also tried some recipes I've found online. Most of them have come out great, but lately I've had a few disappointments. It's extra disappointing because you make your soap, then have to wait 8 weeks to see how it came out. So if it's no good, that's a pretty big waste of time.

Yesterday I wrote two recipes. A Triple Butter soap and a Shea Butter soap with a high percentage of shea butter. I was a little nervous about the high percentage of shea affecting the lather, and didn't want to wait 6-8 weeks to see, so I decided to make a half pound hot process batch for each recipe. When you do HP (hot process) the soap is ready to use right away because you essentially cook out the lye. Although a 1-2 week curing time is best. The look of HP soap is a little different from CP, and you can't do as many swirls and designs as you can with CP, but it does have it's benefits. The main one being the short cure time.

When testing out a new recipe, using the HP method can save a lot of time. If it comes out the way you hope, you can leave it, or switch to CP. Those of you who make handmade soap may want to try this as well. I went natural for both recipes, no color and no fragrance, just naked soap. This way you get to see how the soap is on its own, and you get an idea of how fast it moves and how much color you may need for future batches.

Here is a picture showing the difference between CP & HP. The darker soap is CP. HP thickens the soap during the cook, so you really don't get a smooth pour when molding it. It usually has to be spooned into the mold, hence the chunky looking top.

Yesterday I wrote two recipes. A Triple Butter soap and a Shea Butter soap with a high percentage of shea butter. I was a little nervous about the high percentage of shea affecting the lather, and didn't want to wait 6-8 weeks to see, so I decided to make a half pound hot process batch for each recipe. When you do HP (hot process) the soap is ready to use right away because you essentially cook out the lye. Although a 1-2 week curing time is best. The look of HP soap is a little different from CP, and you can't do as many swirls and designs as you can with CP, but it does have it's benefits. The main one being the short cure time.

When testing out a new recipe, using the HP method can save a lot of time. If it comes out the way you hope, you can leave it, or switch to CP. Those of you who make handmade soap may want to try this as well. I went natural for both recipes, no color and no fragrance, just naked soap. This way you get to see how the soap is on its own, and you get an idea of how fast it moves and how much color you may need for future batches.

Here is a picture showing the difference between CP & HP. The darker soap is CP. HP thickens the soap during the cook, so you really don't get a smooth pour when molding it. It usually has to be spooned into the mold, hence the chunky looking top.

Friday, November 2, 2012

Emulsification

Before we begin talking about anything, the first thing we need to know about is emulsification. What is it? Emulsification is when we take oil and water, two things that do not naturally mix, and bring them together in one homogeneous mixture. This is achieved by using an emulsifier, such as Polawax. There is a vast number of emulsifiers to choose from. We can use a self-emulsifying agent by itself, or using the HLB system you can make your own emulsifier by using 2 ingredients, one with a high HLB value, and one with a low HLB. An emulsifier is an ingredient with a hydrophilic head, which means water loving, and a lipophilic tail, which means oil loving. By using these ingredients, we are able to uniformly hold water and oil together in an emulsion.

Lotions, creams, conditioners, even some body washes and scrubs are emulsions. When oils and water based ingredients are brought together and mixed, it turns white and creamy. That's what gives lotion its opaque look. All emulsions are made in different phases. We have the water phase, which would be your water, water based ingredients, and ingredients that are soluble in water. The oil phase, which is any oils, butters, fats, lipids, emulsifiers, and other oil soluble ingredients. Both of these phases are heated separately, to about 170F and held for 20 minutes. Then, the magic happens. After heating & holding both phases, they are mixed together, resulting in emulsification of both phases. After mixing and letting cool a bit, any ingredients that are heat sensitive are added and mixed in. This is called the cool down phase.

There are a few different keys to making a successful emulsion.

Most importantly, an emulsifying agent is needed to bring the water and oil phase together.

Second, we need heat for everything to mix together.

Lastly, we need plenty of mixing to ensure the phases stay together and don't separate over time.

Without these important factors, we get a failed emulsion. The water and oil will separate, sometimes with just some oil leaking out, sometimes we get complete separation, with the creamy oil layer on top and a watery layer on the bottom. It can happen right away, after a few days, or it can happen after a while. There is always something to be learned from a lotion fail, and we can usually figure out what we did wrong so we know what not to do next time!

Now that we've learned about emulsification, we can begin learning about how to make products and emulsions of our own!

Lotions, creams, conditioners, even some body washes and scrubs are emulsions. When oils and water based ingredients are brought together and mixed, it turns white and creamy. That's what gives lotion its opaque look. All emulsions are made in different phases. We have the water phase, which would be your water, water based ingredients, and ingredients that are soluble in water. The oil phase, which is any oils, butters, fats, lipids, emulsifiers, and other oil soluble ingredients. Both of these phases are heated separately, to about 170F and held for 20 minutes. Then, the magic happens. After heating & holding both phases, they are mixed together, resulting in emulsification of both phases. After mixing and letting cool a bit, any ingredients that are heat sensitive are added and mixed in. This is called the cool down phase.

There are a few different keys to making a successful emulsion.

Most importantly, an emulsifying agent is needed to bring the water and oil phase together.

Second, we need heat for everything to mix together.

Lastly, we need plenty of mixing to ensure the phases stay together and don't separate over time.

Without these important factors, we get a failed emulsion. The water and oil will separate, sometimes with just some oil leaking out, sometimes we get complete separation, with the creamy oil layer on top and a watery layer on the bottom. It can happen right away, after a few days, or it can happen after a while. There is always something to be learned from a lotion fail, and we can usually figure out what we did wrong so we know what not to do next time!

Now that we've learned about emulsification, we can begin learning about how to make products and emulsions of our own!

Subscribe to:

Posts (Atom)